Boost Performance With Undercarriage Parts and Its Utilizes

Recognizing the detailed elements that compose the undercarriage of heavy machinery is critical for firms intending to maximize their functional effectiveness. From track footwear to sprockets and idlers, undercarriage parts play a crucial duty in the efficiency and long life of devices. The calculated usage of these components can cause considerable renovations in productivity and price savings. Let's discover exactly how services can harness the power of undercarriage parts to streamline their operations and drive success in an open market.

Value of Undercarriage Parts

Normal maintenance and prompt replacement of undercarriage components are vital to stop expensive downtime and maximize productivity. Worn-out undercarriage parts can result in lowered traction, enhanced gas intake, and accelerated endure other components of the machinery. By spending in top notch undercarriage components and adhering to a stringent maintenance timetable, drivers can maximize the performance of their heavy equipment and prolong its service life.

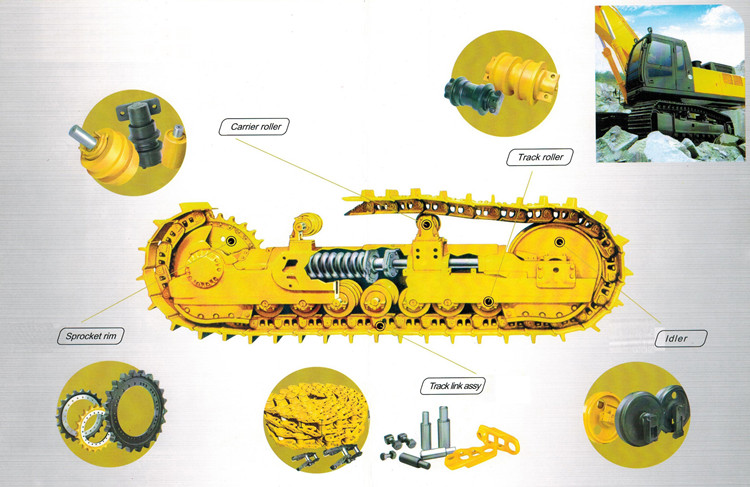

Common Types of Undercarriage Parts

Crucial elements vital for the efficient operation of heavy machinery, undercarriage components play a critical role in guaranteeing optimal efficiency and long life of the equipment. Some common kinds of undercarriage components consist of track chains, track footwear, rollers, idlers, gears, and track structures. Track chains are accountable for transferring the machine's weight and providing traction, while track footwear sustain the device's weight and protect the track chain from wear. Rollers aid in assisting the track and enhancing its resilience, while idlers assist regulate the track tension and minimize wear on the track system. Sprockets engage with the track web links and provide the driving force for the equipment's movement. Track frameworks serve as the primary framework supporting all the undercarriage components. Understanding the function and significance of these usual undercarriage components is essential for keeping heavy machinery in optimal functioning condition, lowering downtime, and making best use of efficiency on work sites. Regular examination, upkeep, and timely substitute of these parts are essential variables in making sure the total effectiveness of heavy tools.

Benefits of Regular Upkeep

Enhancing functional efficiency and extending devices life expectancy, routine upkeep of undercarriage components is essential for maximizing heavy machinery performance. By adhering to an organized upkeep timetable, drivers can reduce and avoid expensive break downs downtime. Regular assessments and maintenance of undercarriage components such as tracks, idlers, sprockets, and rollers not only guarantee smooth procedure yet also add to total safety and security on task websites.

Enhancing Tools Performance

In addition, choosing the appropriate undercarriage components for particular operating problems is important. When picking undercarriage parts, factors such as the type of surface, workload, and ecological conditions should be taken right into consideration. Making use of top notch components that are designed to endure the demands of the work can enhance general equipment efficiency and long life.

Moreover, maintaining undercarriage components well-lubricated and clean is vital for smooth operation. Dust, debris, and lack of lubrication can cause early wear and tear on elements, Find Out More causing lowered efficiency and potential break downs. Normal cleaning and lubrication regimens can assist avoid these issues and ensure consistent tools efficiency.

Economical Solutions for Businesses

To enhance undercarriage components successfully and ensure long-lasting tools performance, services should prioritize economical options that straighten with their operational needs and budget plan restrictions. Buying premium undercarriage components can bring about substantial savings in the future by reducing downtime, maintenance expenses, and the danger of unexpected equipment failures. One cost-efficient remedy for organizations is to execute a positive upkeep routine that consists of normal evaluations, lubrication, and prompt substitute of damaged undercarriage parts. By identifying and attending to prospective issues at an early stage, services can prevent costly repair work and expand the lifespan of their equipment.

Furthermore, businesses can discover different undercarriage parts such as aftermarket components that meet sector criteria and specs at a reduced cost than OEM components. By thoroughly evaluating their choices and partnering with reliable suppliers, services can effectively manage their undercarriage component expenditures without jeopardizing on performance or integrity.

Conclusion

In final thought, undercarriage parts play a crucial duty in improving devices performance and efficiency. It is clear that undercarriage components are indispensable parts for organizations looking to increase efficiency and maintain their devices in optimum condition.

From track shoes to sprockets and idlers, undercarriage parts play a vital function in the performance and durability of equipment.The relevance of undercarriage parts in hefty equipment can not be overstated, as they are vital parts that significantly affect the total performance and durability of the tools.Vital components important for the reliable procedure of heavy machinery, undercarriage informative post components play a crucial role in guaranteeing optimum efficiency and long life of the equipment.Enhancing operational effectiveness and lengthening tools lifespan, regular maintenance of undercarriage components is essential for optimizing heavy equipment performance. Additionally, services can discover different undercarriage components such as aftermarket components that satisfy market standards and specifications at a reduced price than OEM components.